Capabilities

At MOKOMEDTECH, we continue to introduce top-notch equipment and technologies to improve our capabilities so we can better support our customers.

Home » Capabilities

Our Medical Electronics Manufacturing Capabilities

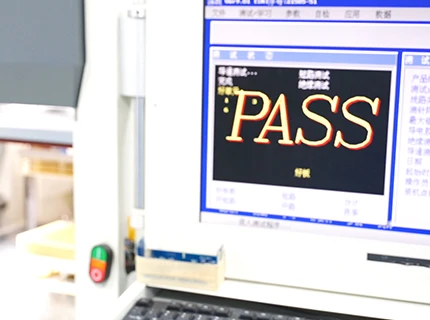

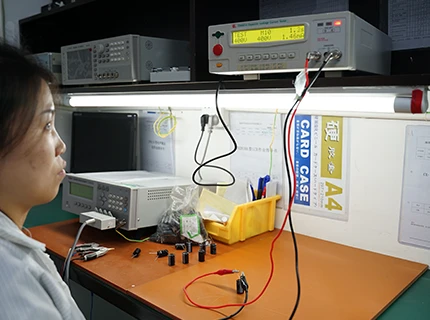

Clean Room Manufacturing

• Sterile Packaging& Labeling

• 100% ESD components control

• 5 SMT lines+ 3 DIP lines

• 30,000 square meter PCB Per Month

• 100,000,000 Units PCB Assembly Per Month

• Box Build Assembly

• Cable & Wire Harness Assembly

Injection Molding

MOKOMEDTECH is equipped with industry-leading injection molding equipment, from small batches to large batches, simple to highly complex projects, we can provide customers with fast and high-quality injection molding services:

• Overmolding

• Insert Molding

• Micromolding

• Handle Most Thermoplastic Materials

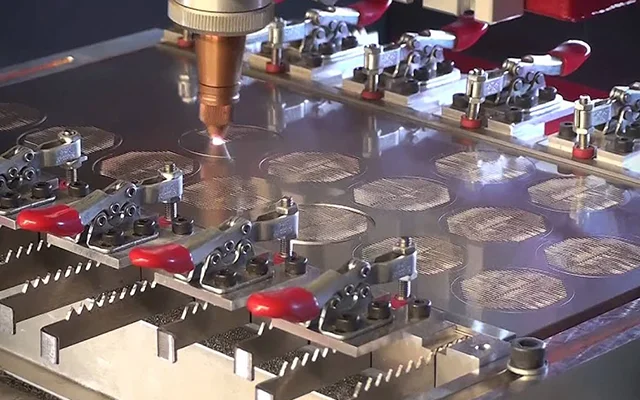

Precision Laser Cutting

• Capable of handling various materials including Nitinol, stainless steel, tantalum, and other alloys

• Cut different material forms such as tubes, strips, and sheets

• Electropolish finishing

• Cut tolerance of +/- 0.0003 inch

• Precision burr-free laser cutting

Welding

• Laser Welding

• Resistance Welding

• Ultrasonic Welding

• Soldering

• Fusion of many materials – metals and plastics

• Hermetic Enclosure Capabilities

CNC Machining

• CNC 5-Axis, 7-Axis, and Multi-Axis Machining

• CNC 3-Axis, 4-Axis Milling

• CNC turning

• Stamping

• Forming

• Needle sharpening

• EDM Fine-Hole Drilling

Visit Our Factory

Talk to Us

Find out more about what we can do for your electronic device manufacturing project