In the intricate world of medical device manufacturing, adherence to international quality management standards is paramount. These standards not only ensure the safety and effectiveness of medical devices but also play a pivotal role in building trust among healthcare professionals and patients alike. Two prominent standards, ISO 13485 and ISO 9001, are frequently mentioned in this context.

In this article, we will demystify the differences between ISO 13485 and ISO 9001, specifically tailored for medical device manufacturers. By exploring the fundamental aspects and key distinctions of these standards, you can learn where medical device manufacturers need to improve quality standards. After reading this article, you can also figure out whether you need to comply with both standards or just one of them.

Before delving into these differences, it is critical to understand the essence of these two standards individually.

What Is ISO 9001?

ISO 9001, known as the International Organization for Standardization’s (ISO) flagship quality management standard, provides a comprehensive framework for organizations across various industries. It is the universal quality management standard, applicable to companies of any form, size, and industry. It establishes a set of requirements for implementing a quality management system (QMS) that enhances customer satisfaction, improves internal processes, and promotes continual improvement. ISO 9001’s overarching objective is to help organizations consistently deliver products and services that meet customer expectations while adhering to applicable regulatory requirements.

What Is ISO 13485?

On the other hand, ISO 13485 is a specialized standard specifically designed for the medical device industry. It focuses on the unique aspects and stringent regulatory requirements governing the development, production, and distribution of medical devices. ISO 13485 provides an internationally recognized framework to establish and maintain a QMS that ensures the safety and efficacy of medical devices throughout their life cycle. Compliance with ISO 13485 is often a prerequisite for regulatory approvals in many countries, demonstrating a manufacturer’s commitment to meeting the highest quality standards in the medical device industry.

ISO 13485 vs ISO 9001: Similarities

ISO 13485 and ISO 9001 are both internationally recognized standards developed by the International Organization for Standardization (ISO). While they are different in terms of their specific focuses, there are several similarities between the two standards. Here are some of the key similarities:

1. Quality Management Systems (QMS)

Both ISO 13485 and ISO 9001 are based on the concept of implementing and maintaining a robust quality management system. They provide a framework for organizations to establish processes, procedures, and policies to ensure consistent quality and continuous improvement.

2. Risk Management

While risk management is more explicit in ISO 13485, it is also a key consideration in ISO 9001. Both standards encourage organizations to identify and assess risks and implement appropriate controls to mitigate or manage those risks effectively.

3. Customer Focus

Both standards emphasize the importance of meeting customer requirements and enhancing customer satisfaction. They encourage organizations to understand customer needs, monitor customer feedback, and strive to exceed customer expectations.

4. Process approach:

ISO 13485 and ISO 9001 promote a process-based approach to quality management. This means that organizations are encouraged to identify, document, and monitor key processes throughout their operations, ensuring that they are well-defined, controlled, and continually improved. Although ISO 13485 and ISO 9001 don’t have the same structure, they both use a PDCA cycle, the continuous quality improvement model consisting of a logical sequence of four repetitive steps for continuous enhancement to a product or service.

5. Internal Audits and Management Reviews

ISO 13485 and ISO 9001 both require organizations to conduct internal audits of their quality management systems and perform regular management reviews. These activities help ensure that the system is functioning properly, identify areas for improvement, and drive ongoing effectiveness.

6. Documentation Requirements

ISO 13485 and ISO 9001 both require organizations to establish and maintain documented procedures and records to demonstrate the effective operation of their quality management systems. Documentation is essential for ensuring consistency, traceability, and accountability.

7. Management Responsibility

Both standards highlight the role of top management in driving and supporting the quality management system. They require management commitment, leadership, and involvement in establishing quality objectives, allocating resources, and ensuring the effectiveness of the system.

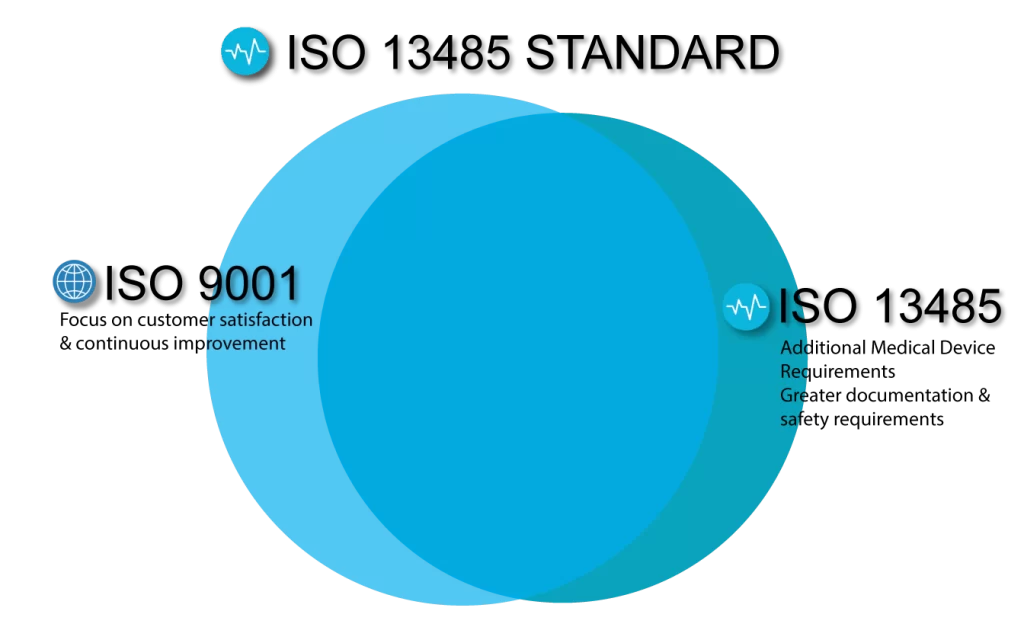

While ISO 13485 specifically focuses on the requirements for medical devices and related services, and ISO 9001 is a general quality management standard applicable to various industries, these similarities allow organizations to leverage common principles and practices when implementing and maintaining their respective management systems. However, there are several differences between these two standards.

Difference Between ISO 13485 VS ISO 9001

ISO 13485 and ISO 9001 are both international standards that relate to quality management systems (QMS), but they have different focuses and applications within the medical device industry. Here are the key differences between ISO 13485 and ISO 9001:

1. Scope and Applicability

ISO 9001: It is a general quality management standard applicable to any industry or organization, regardless of its products or services.

ISO 13485: It is specifically designed for the medical device industry and focuses on the quality management system requirements for the design, development, production, installation, and servicing of medical devices.

2. Regulatory Compliance

ISO 9001: It does not address specific regulatory requirements or provide guidance on meeting regulatory obligations. However, it can serve as a foundation for compliance with applicable regulations.

ISO 13485: It incorporates specific regulatory requirements from various global medical device regulations, such as the European Medical Device Regulation (MDR) and the U.S. Food and Drug Administration (FDA) requirements. ISO 13485 can help organizations demonstrate compliance with these regulations.

3. Risk Management:

ISO 9001: It does not explicitly require a formal risk management process. Risk management may be addressed indirectly based on the context and requirements of the organization.

ISO 13485: It explicitly requires organizations to establish and maintain a risk management process throughout the product lifecycle. It emphasizes identifying, assessing, controlling, and mitigating risks associated with medical devices.

4. Documentation and Records:

ISO 9001: It provides flexibility in terms of documentation requirements, allowing organizations to determine the necessary documentation based on their needs and processes.

ISO 13485: It has more specific documentation requirements, including the need for procedures for device documentation, validation, traceability, and control of records. Documentation plays a critical role in demonstrating compliance with regulatory requirements.

5. Focus on Product:

ISO 9001: It emphasizes customer satisfaction and focuses on meeting customer requirements and enhancing customer experience.

ISO 13485: It places greater emphasis on product safety and performance, as well as regulatory compliance. The standard requires manufacturers to demonstrate the effectiveness of their quality management system in ensuring the safety and performance of medical devices.

6. Continual Improvement:

ISO 9001: It emphasizes continual improvement in all aspects of the organization’s operations and processes, including customer satisfaction.

ISO 13485: It also emphasizes continual improvement but focuses on the effectiveness of the quality management system in meeting regulatory requirements and maintaining the safety and performance of medical devices.

While ISO 9001 can be a useful starting point for implementing a quality management system in the medical device industry, ISO 13485 provides a more specific framework tailored to the unique requirements of medical device manufacturers. Organizations in the medical device industry often choose to pursue ISO 13485 certification to demonstrate their commitment to quality and compliance with regulatory requirements.

Medical device manufacturers who meet both ISO 13485 and ISO 9001 standards

Comparing ISO 13485 with ISO 9001 reveals the wide range of actions that medical device manufacturers must take to ensure product quality. ISO13485 builds on ISO9001 while imposing additional requirements for effective management, documentation, and measurement to produce safe medical devices.

MOKOMEDTECH understands deeply that medical products have a direct impact on the health and safety of users. That is why every product must be manufactured to the highest quality standards. From the procurement of raw materials to the entire production process, MOKOMEDTECH strictly adheres to the regulations of the medical industry. The medical devices we manufacture are registered with the FDA and our certifications include ISO13485, ISO9001, ISO 14001, BSCI, and UL, which proves that we never compromise on quality. Solutions designed to ISO 13485 can streamline your certification time and create automated workflows that help your organization meet the requirements throughout the product lifecycle.