Due to the aging of population and lack of public health resources, the retail market of home medical device is looking good recently. If you project team plan to devote to it with a outstanding design, maybe the next key step is sourcing a proper manufacturer for home therapy equipment, which does well in hot and cold therapy equipment, pain relief stimulator, and other various product ranges.

Nevertheless, it is a home therapy equipment manufacturer that is looking for. According to its characteristics, more sourcing considerations should be reminded than other common goods.

Smart Hardware Manufacture Ability

It is recommendable to look into the PCB manufacture ability of the factory. PCB is the key to the automation level of your design. Home therapy equipment essentially aims at helping patients at home. In other words, it should replace the therapy operation of a nurse with automatic function available.

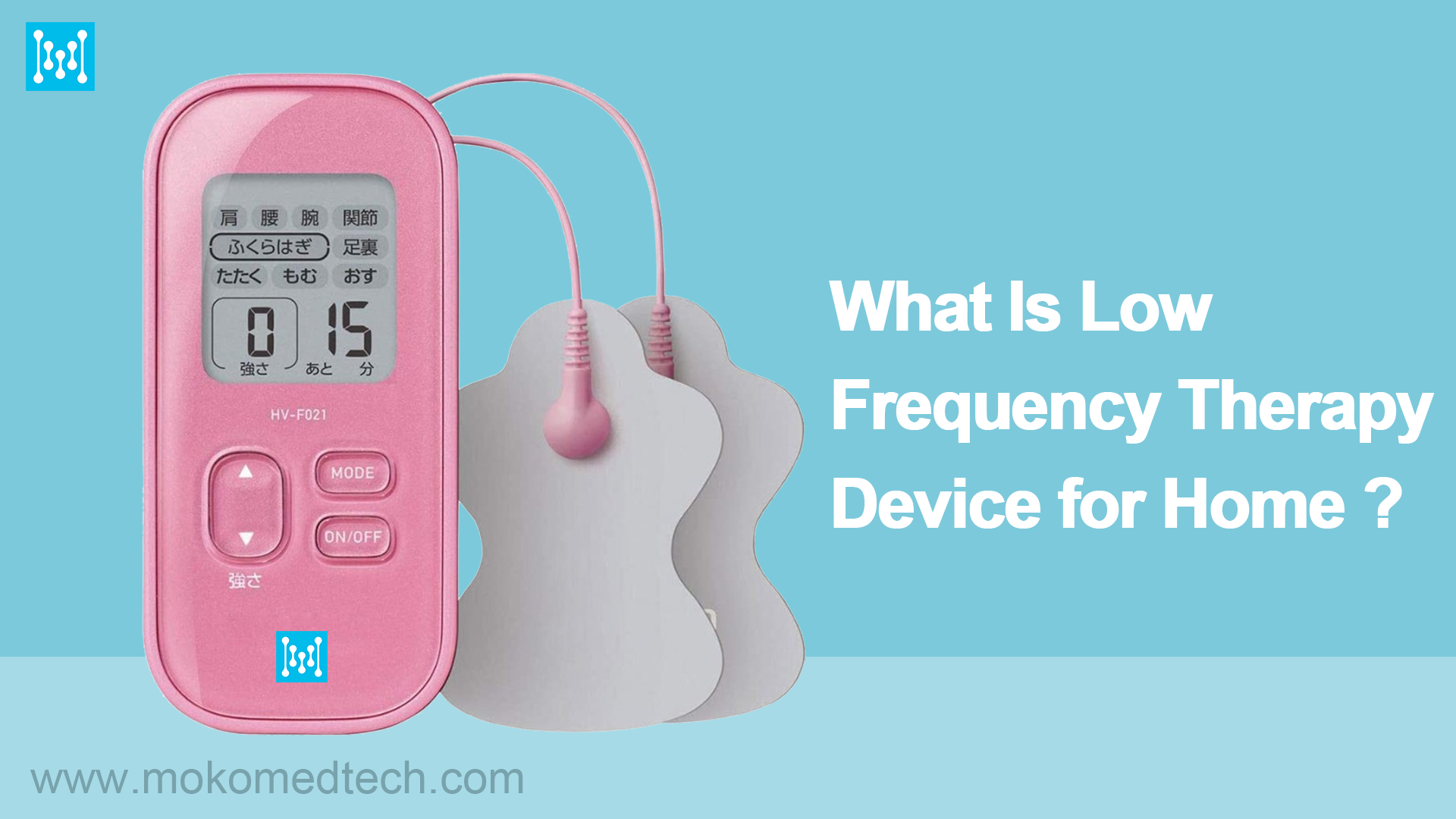

We still take pain relief stimulator manufacture for an example. Eight massage modules are optional according to different stimulation approaches. Besides, ninety levels of stimulation intensity are available. What’s more, it was configured by automatic timekeeping function. These designs entirely imitate a professional nurse to conduct muscle pain relief massage on your body.

In order to carry these complex functions in just a little main device, PCB should embrace complex circuit design within a complex construction. Moreover, any tiny mistake during batch production can lead to failure of the whole circuit board. Besides, home therapy equipment is usually designed in a small size for saving room space, so fine processing is indispensable.

PCB Category Coverage

The more PCB category it can produce, the higher technique it can contain. Multiple PCB, FR4 PCB and metal core PCB are good carrier to free your high-tech ideas.

Single PCB and multiple PCB

For a single board, all parts are installed on one side, while all wires are concentrated on the other side. Obviously, single board name after its features that wire only appears on one side. However, there are many restrictions on the design circuit of the single-sided panel. For example, wiring cannot cross but must go around a separate path. Thus, single PCB is seldom used except for primitive circuits.

PCB multiple board refers to a multiple circuit board mainly used in electrical products. The multiple PCB contains more boards than single or double PCB. Compared with the single PCB, the significant distinguish of the double-panel is the installation of ground plane and internal power layer which maintains the inner electrical layer.

Complex devices, such as pain relief stimulator, with a large number of components and circuits benefit from the use of multi-layer PCBs. Pain relief stimulator with various massage modules and strength require this complexity.

Although there are a few layers, the board is capable of offering high operating capacity and speed, making them especially suitable for advanced equipment. That means they can service patient with sensitive response according to his order.

As device miniaturization becomes a growing trend, the use cases for multi-layer PCBs will only increase. Multiple PCB fits these trend a lot. For example, most of us prefer mini main device of pain relief stimulators for easy holding, moving and placing at home.

Last but not least, many multi-layer boards even features its impedance control and EMI shielding, further improving the quality of the board and device.

FR4 PCB

FR4 is a standard for glass fiber reinforced epoxy resin compounds defined by National Electrical Manufacturers Association. Within, FR means flame retardant in English. It indicates that the material meet the standards of UL94V-0 flammability of plastic materials. Formally, code 94V-0 would be found on all qualified PCBs.

In case that the material catches fire, it can stop the the spreading of fire. For those made from high TG or HiTG, its glass transition temperature (TG) is 115°C to 200°C, which means FR4 can sensitively response to the fire. For home therapy equipment, it is not bad to possess this type of PCB so as to ensure household fire safety.

In addition, FR4 features an excellent strength-to-weight ratio. It does not absorb water and maintains high mechanical loads as well as insulating capacity in dry or wet environments.

FR-4 PCB has been widely used in electronic products, such as home therapy device, communication, computers, digital circuits, industrial instrumentation, automobile circuits and so on. Its performance could meet the needs of general industrial electronic products with beautiful cost .

Mental Core PCB

Wonderful physical properties enable these PCBs to be broadly used in various home therapy equipment.

First, it has high thermal conductivity. Though PCB with FR4 is good at fire safety, weaker inter-layer insulation and lower thermal conductivity may result in the rise of internal temperatures and bad effect on surrounding internal parts, without proper heat dissipation. Conversely, a metal PCB made of aluminum has excellent thermal conductivity which play a vital roles in maintaining proper temperatures inside the device.

Second, metal core PCBs show good dimensional stability compared to FR4 PCB. It is suggested that when an aluminum PCB is heated from thirty degrees Celsius to one hundred and fifty degrees Celsius, its size would only expand 2.5-3%.

Third, it does well in thermal expansion. Coefficient of thermal expansion is a term used to describe the expansion or contraction of a substance at temperature. The CTE of aluminum and copper is higher than common FR4, and the thermal conductivity is 0.8~3.0 W/cK.

PCB Manufacturing Accuracy

High manufacturing accuracy can ensure product quality, so you need to add it to the factory evaluation form.

High-precision circuit boards mean the use of technologies such as fine line width/spacing, tiny holes, narrow ring width, buried and blind holes to achieve stable quality and high density.

To improve product accuracy, some manufacturing machines, such as EDM fine-hole drilling CNC machine, laser exposure machine, AOI testing machine and horizontal production line, are very useful.

Smart Firmware R&D Potential

And, you’d better to pay attention to any availability and possibility of smart firmware R&D team in your targeted manufacturer for home therapy equipment. Still take pain relief stimulator as an example. Your retail customer must use it at home without professional instruction.

This potential of factory may potentially pave your way to high-tech breakthrough for product development in the future, even though you have no idea about how IoMT works between at-home patient and hospital now.

Firmware is a bridge between the software and the hardware. It can read and write programs in EPROM or EEPROM. With the help of the firmware, the software implements the operation of a specific machine according to the standard device driver.

Plastic Component Manufacture Capacity

After hardware and firmware, plastic production capacity is the third important consideration for sourcing medical device. As you can see, hot and cold therapy equipment contains a lot of plastic parts – a handle, a lid, a bucket and some plastic items connected to the tube. A formal home therapy equipment must be made of a few plastic parts in different shape.

We high advise to fine a factory which have a good command of 3D printing. Or, at least, before mold manufacturing in the field of industrial design, you need to make a sample by 3D printer to double-check your design. 3D printing is a kind of prototyping technology, which features its printing efficiency. It is a technology grounded on digital model files. It prints objects with bondable materials such as powdered metal or plastic toby layer by layer.

3D printers can improve the efficiency of sample making and reduce costs. Relying on the computer, it directly produces various parts or models of home therapy device parts without other equipment to assist.

In particular, home therapy devices consist of plastic casings of various shapes, but it is often necessary to consider each physical sample before making mold for batch production. Traditionally speaking, making a sample involves many processing machines and even multiple production lines to complete the assembly. Conversely, with a 3D printer, a complete tangible sample can be obtained without mold making and other operations. This not only saves lots of time, but also saves a lot of labour and raw materials.

In addition to 3D printing, injection molding and automatic production line are indispensable factors to evaluate an OEM factory.

Metal Component Process Versatility

When it comes to, again, home therapy equipment manufacturer, versatility and accuracy of processing metal parts have a significant effect on realizing your innovative design.

It is highly recommended to choose a factory for home therapy device with CNC milling, CNC turning, EDM, surface grinding technique. These would greatly enhance the quality and produce efficiency of fine metal.

CNC machine tools process parts automatically according to pre-programmed processing programs. It is capable of grooving, drilling, reaming, and reaming and so on.

It is very suitable for the diversity and complexity of metal parts of home therapy equipment. First, it features high processing precision and stable processing quality. Second, it can perform multi-coordinate linkage and process parts with complex shapes. If you want to change components, just modify the NC program. This can save production preparation time. Third, you can choose a favorable processing amount without any worried about product deformation, because CNC machine is very stable in operation. Last but not least, CNC machines have a great command of automation, which can reduce labor intensity.

Accessory Supplier Manageability

Last but not least, supplier management ability of the factory should not be ignored. And this, coincidentally, is partly taken care of by the system we will mention in next part. Some outsourcing accessories, such as electrode sheets of pain relief stimulator, the cloth bandage of hot and cold therapy equipment, should be properly supplied in case of bringing bad effects to the complement of the main body of devices.

Quality Assurance

If possible, ask for any quality assurance certificate when selecting manufacturers.

Home therapy equipment is a type of medical device whose quality system is distinguished as ISO9001. ISO13485 adapts the EU Medical Device Directive (MDD), the EU Medical Device Regulation (MDR) and other regulations, bringing a professional guide of quality management to medical device manufacturers. Meanwhile, it provides a visible chance for medical device manufacturers to show integrated quality competence, and it also demonstrates the company’s commitment to medical device safety and quality.

A manufacturer with ISO13485 management system promises stable quality and effective response to quality risk. This brings safeguard to your retail customers and enhances the reputation of your brand. We are in the field of medical devices, so we should not bring extra hidden danger to those suffering from sickness. Moreover, stable product quality is beneficial to the sustainable expansion of your business.

Other Universal Considerations

The above considerations are special for home therapy devices, which usually contain lots of components and high-tech parts. And, issues of common purchase should not be forgotten, too, such as cost performance, good delivery, experience, after sales and so on.

Conclusion

We sincerely hope you can find your congenial manufacturer for home therapy equipment.

Continue reading as follows